Meyer Foodsafety

Language

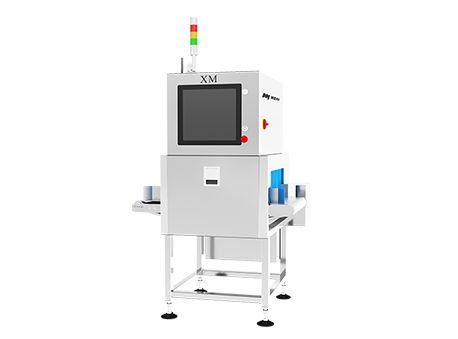

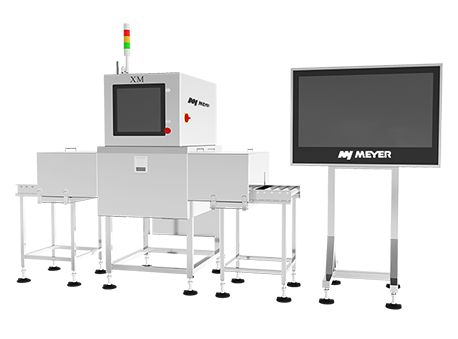

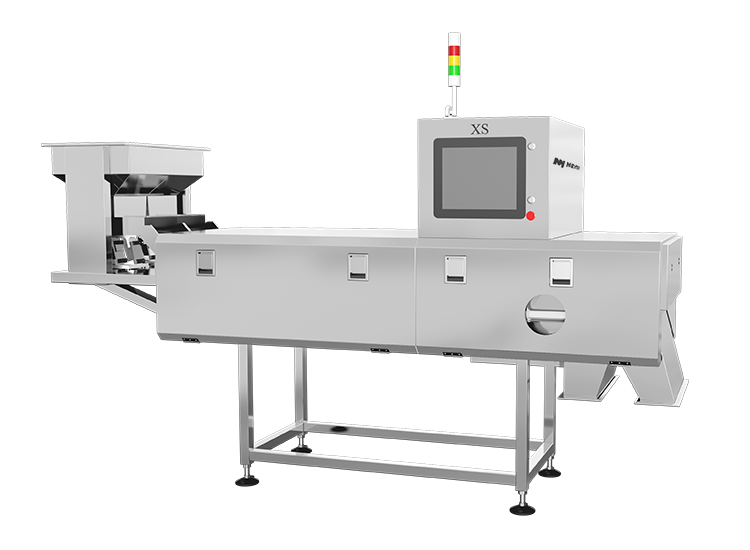

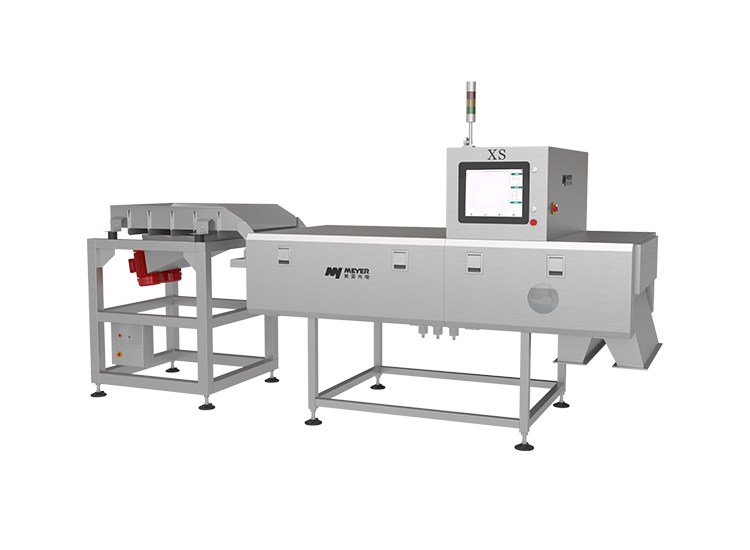

XS Series X-Ray Inspection Machine for Food Material

Beryllium window source for accurate inspection of high-density impurities

AI deep learning technology to deal with complex impurities and defects

Select:

60XS

60XS 80XS

80XS 120XS

120XS

Product Introduction

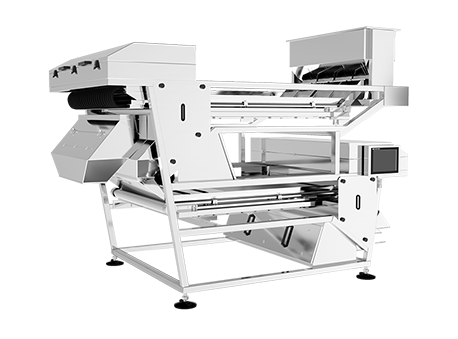

☛ Widely used in beans, nuts, seed kernels, peanuts, fruits and vegetables, tea, aquatic products and other food materials sorting. Effectively removing glass, metal, stone, ceramics and other high-density impurities, as well as worm eaten, hollow and other defects.

Application Field

Product Specificities

More Specificities

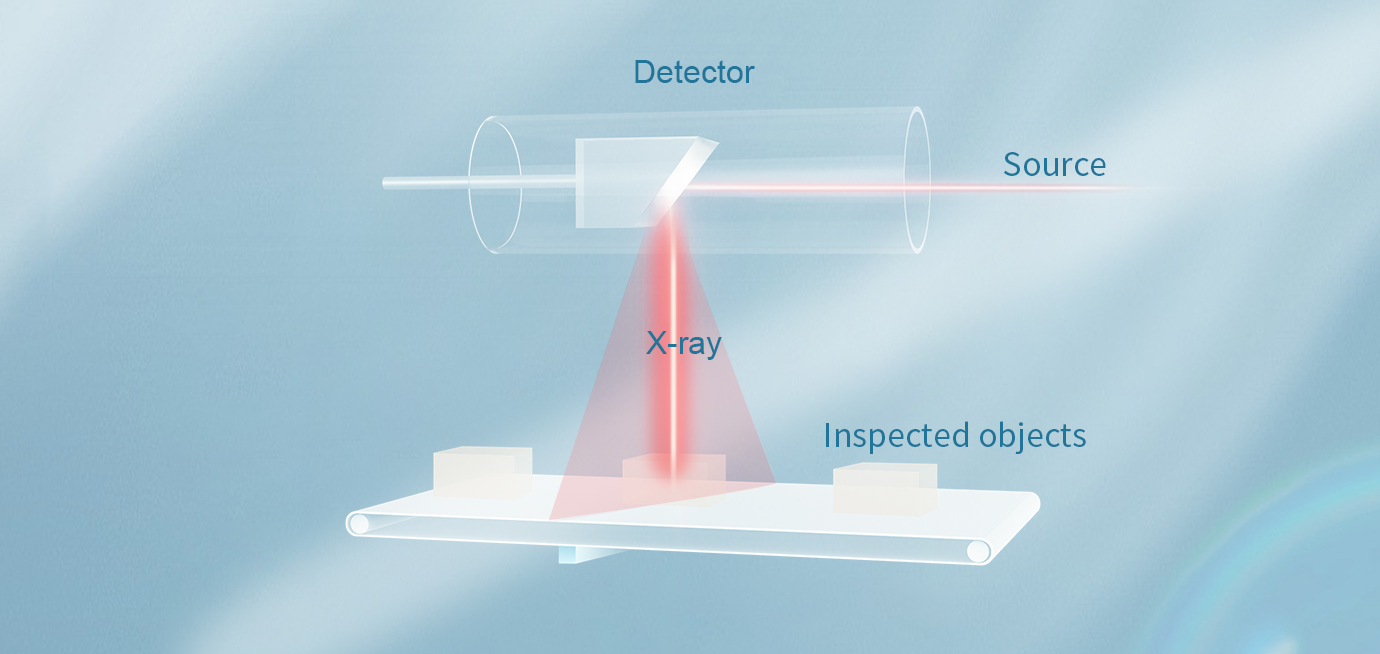

X-Ray Imaging Technology

Using the international advanced beryllium window source, the imaging is clearer, and foreign objects with similar density can be easily identified.

Maglev Ejector 3.0

Using a new integrated connection structure, can achieve ultra-high-speed response, more accurate rejection, up to 1200 times per second; millisecond start-stop,direct gas supply, lower loss; standardized design, unmanned production, longer service life, more convenient maintenance.

Intelligent Anti-shattering Technology

Through the targeted rejection algorithm and soft landing design, reduces the stress on the material and maximizes the control of breakage.

Simple Interface

Modular UI design makes the operation more simple; built-in learning package that you can easily get training courseware.

Intelligent Alarm

Equipped with visual LED, so that the signal, light, air pressure and other abnormal conditions can be easily detected and solvedc, making the processing process more assured.

Remote Service

PC/mobile control, can provide online after-sales service such as commissioning, physical examination, maintenance guidance.

Technical Specifications

| Model | MY8045-60XS/MY8060-80XS |

| Configuration(mm)(L*W*H) | 2530X1100X2200/2530X1250X2400 |

| Net weight(kg) | 580/680 |

| Conveyor belt width(mm) | 570/720 |

| Size of materials(mm) | Width≤450, Height≤35/Width≤600, Height≤35 |

| Conveyor belt speed(m/min) | 10-20(adjustable) |

| Operating environment | Ambient temperature 0-40℃, relative humidity 30-85% No condensation, no freezing, upheaval |

| Voltage | AC220V±10%, 50Hz±3, 2.5kw |

| Air pressure | 0.6-0.8MPa |

| Air consumption | <0.3m3/min |

| X-ray output | Beryllium350W, Max80kV/8.0mA |

| Sensitivity(mm) | SUS ball≥∅0.3 |

| Interface | 17 inch LCD touch screen |

More Products

MORE INFORMATION?

Professional instruction will be offered with your contact information left.

Your privacy will be well protected. Read the Privacy Statement for more details.

-

CONTACT ONLINE

CONTACT ONLINE

-

foodsafety@meyerop.com

-

-

SOLUTIONS

SOLUTIONS