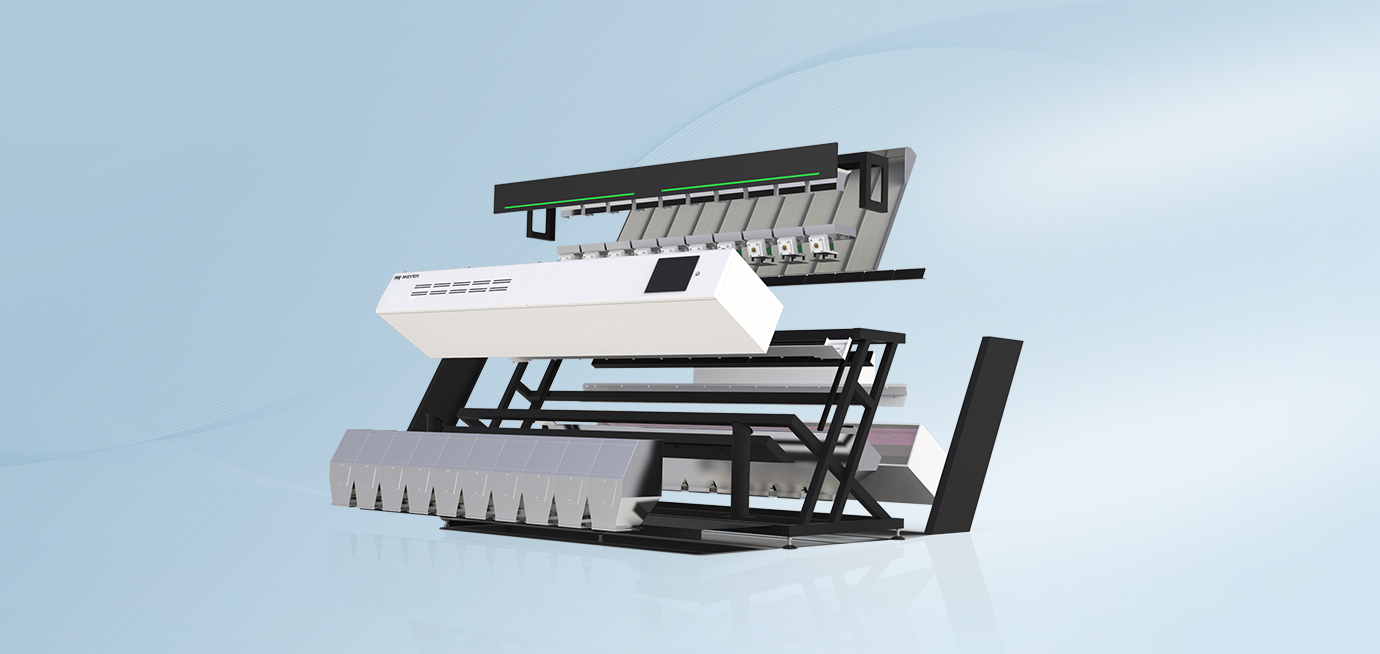

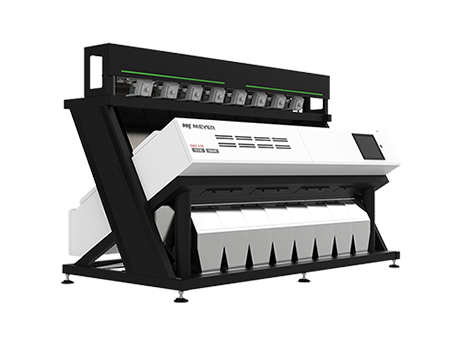

Engineered for stability and performance

Equipped with spectral confocal technology, with certain glass, desiccant sorting ability

240DREAM STANDARD

240DREAM STANDARD 360DREAM STANDARD

360DREAM STANDARD 480DREAM STANDARD

480DREAM STANDARD 600DREAM STANDARD

600DREAM STANDARD 780DREAM STANDARD

780DREAM STANDARD

☛ Suitable for rice sorting and grading, can remove yellow, moldy, discolored, broken, paddy, rice husk and other impurities. Equipped with spectral confocal technology, can remove glass and desiccant, and sorting accuracy follows automatically without manual adjustment.

Using a new integrated connection structure, can achieve ultra-high-speed response, more accurate rejection, up to 1200 times per second; millisecond start-stop,direct gas supply, lower loss; standardized design, unmanned production, longer service life, more convenient maintenance.

| Name | Model |

Power (kw) |

Voltage (V) |

Air Pressure (MPa) |

Air Consumption (m³/min) |

Dimension (L*W*H mm) |

Weight (kg) |

| 240DREAM | MSXC-240RS2 | 2.0 | 180~240 50Hz | 0.6~0.8 | <2.0 | 1891*1564*2020 | 1120 |

| 360DREAM | MSXC-360RS2 | 2.7 | 180~240 50Hz | 0.6~0.8 | <3.0 | 2533*1564*2020 | 1400 |

| 480DREAM | MSXC-480RS2 | 3.4 | 180~240 50Hz | 0.6~0.8 | <4.0 | 2991*1564*2020 | 1750 |

| 600DREAM | MSXC-600RS2 | 4.0 | 180~240 50Hz | 0.6~0.8 | <5.0 | 3583*1564*2020 | 2090 |

| 780DREAM | MSXC-780RS | 5.0 | 180~240 50Hz | 0.6~0.8 | <6.5 | 4435*1620*2020 | 2800 |

-

CONTACT ONLINE

CONTACT ONLINE

-

foodsafety@meyerop.com

-

-

SOLUTIONS

SOLUTIONS