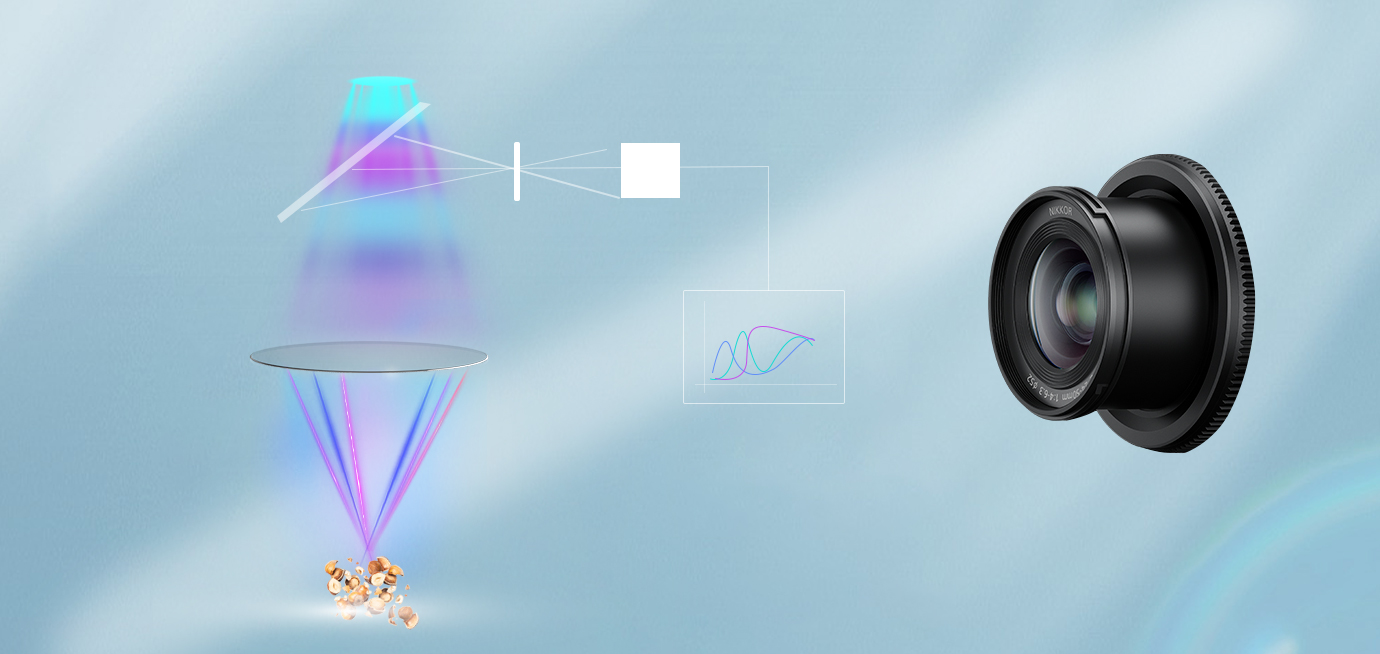

Equipped with InGaAs composite infrared system, realizing the separation of nut shells and kernels

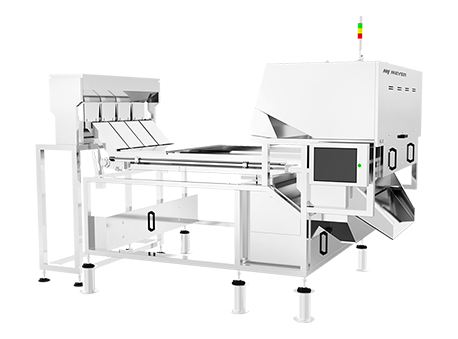

Channel-type structure, the material falls smoothly, large output

60CI

60CI 180CI

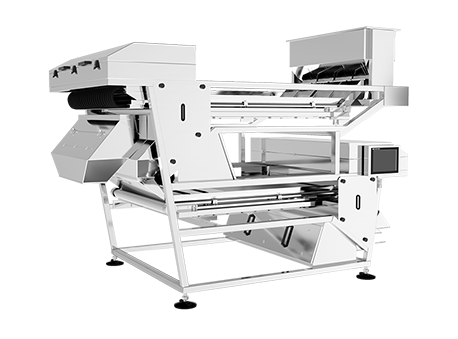

180CI 300CI

300CI

Using a new integrated connection structure, can achieve ultra-high-speed response, more accurate rejection, up to 1200 times per second; millisecond start-stop,direct gas supply, lower loss; standardized design, unmanned production, longer service life, more convenient maintenance.

| Name | Model |

Power (kw) |

Voltage (V) |

Air Pressure (MPa) |

Air Consumption (m³/min) |

Dimension (L*W*H mm) |

Weight (kg) |

| 60CI | 6SXZ-60CI | 2.3 | 180~240 50Hz | 0.6~0.8 | <1.5 | 1136*1700*2030 | 1000 |

| 180CI | 6SXZ-180CI | 4.5 | 180~240 50Hz | 0.6~0.8 | <3.0 | 1628*1700*2030 | 1400 |

| 300CI | 6SXZ-300CI | 6.7 | 180~240 50Hz | 0.6~0.8 | <4.5 | 2220*1700*2030 | 1700 |

-

CONTACT ONLINE

CONTACT ONLINE

-

foodsafety@meyerop.com

-

-

SOLUTIONS

SOLUTIONS