Meyer Tea Champion Color Sorter

This year, Meyer once again won a national honor - Champion Enterprise in Manufacturing Color Sorter. This honor is designed to recognize "long-term focus on certain specific segments of the manufacturing market, production technology or process of international leadership, single product market share among the world's leading enterprises".

Behind the "champion" is the long-term trust and support of our customers. In order to express our gratitude, we will launch a series of reports on the "Road to Champion" to share with you the bits and pieces along the way.

This issue into the tea processing industry ......

With a long and deep history, the tea industry not only carries the mission of cultural heritage, but is also important for economic development. In terms of enhancing the quality and added value of tea, the empowerment of tea technology is crucial.

As a leading enterprise in this field, Meyer has been committed to promoting the mechanization, intelligence and digitalization of tea production since the launch of the first tea color sorter in 2008. The solution achieves full tea species coverage for green tea, black tea, as well as full process coverage for gross tea sorting, refined tea grading, impurity removal and post-packaging foreign impurities detection.

In tea sorting, Meyer company's technology and products have won Anhui Province Science and Technology First Award, National Key New Product and National Science and Technology Second Award. The relevant achievements have been promoted to thousands of domestic tea enterprises, and exported to Vietnam, India, Sri Lanka and South Korea, etc., which have been widely praised and trusted.

The certificates of Meyer tea color sorters

What is the competitiveness of Meyer to be the Champion of color sorter manufacturer?

Breakthrough large output for tea enterprises and tea farmers to increase income!

In the peak season, a color sorter output determines the amount of orders for tea enterprises. However, in the past, the output and the sorting accuracy, carryover rate and other indicators can not be fully balanced. If the output is adjusted, either the rods and pieces in the final product will increase, and the quality of tea leaves will not meet the standard; or the good tea will be mistakenly blown into the rods and pieces, which will reduce the amount of final products.

In order to solve this problem that has been troubling the industry for many years, Meyer R&D engineers went to the customer processing site, constantly verified, and finally found a solution. Through the new TDOA technology, the signal transmission efficiency has been optimized; combined with the ultra-high-speed maglev ejector, milliseconds start and stop, and accurate removing can be achieved even under large production.

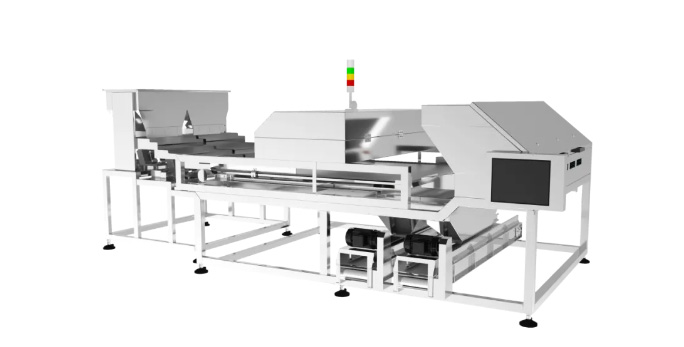

Meyer five-stage tea color sorter

In addition to the conventional sorting needs, the new generation of Meyer color sorter can also achieve multiple classification and grading of tea leaves. For example, Anji white tea with long and short buds; Huangshan Maofeng is divided into single bud, one bud and one leaf, one bud and two leaves and so on.

Meyer tea color sorter can remove all impurities!

At present, brand development has become an important trend in the tea industry. With the help of science and technology, all-round control of malignant impurities in tea can further enhance the quality, avoid customer complaints, and escort the brand.

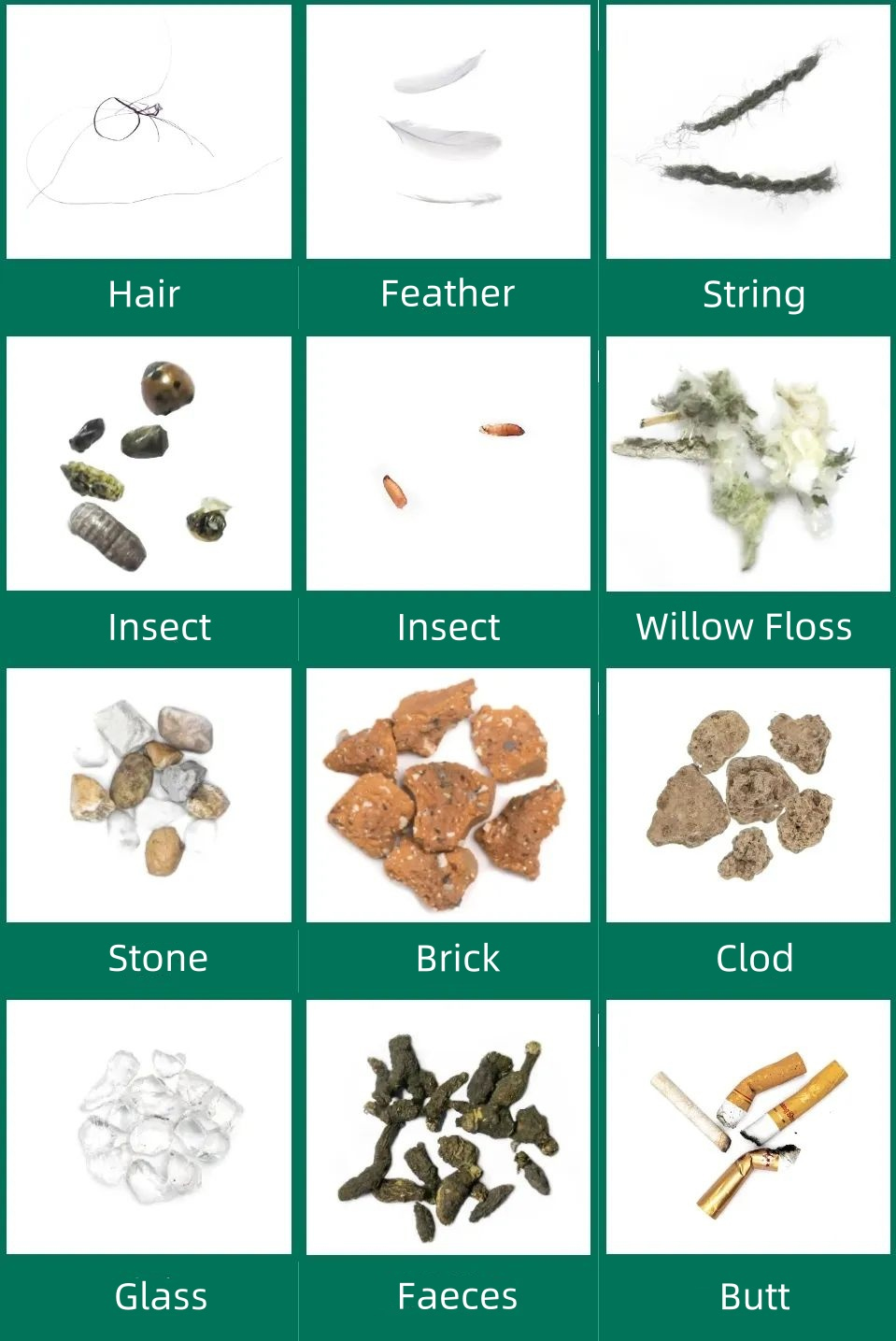

For high-density impurities such as glass, stone, clod, etc., Meyer has an effective solution. But how to effectively remove hair, string, insects and other light impurities is the industry's main problem? Some tea companies have to add manual re-sorting after regular color sorting to ensure quality.

All impurities can be removed

In 2020, a well-known tea enterprise put forward the "No foreign Impurities" standard, at the expense of millions of dollars to introduce a sorting robot from abroad. However, it is difficult for foreign products to match domestic processing scenarios, coupled with high service costs and slow response time, they are unable to meet the tea enterprise's de-contamination needs.

For this reason, they visited many domestic manufacturers of color sorters to seek breakthrough solutions. However, due to the difficulty of technology development and high cost investment, only Meyer succeeded in the challenge to find a sorting solution! Behind this is the belief that Meyer should do what they say they will do!

In order to live up to the customer's expectations, Meyer R&D team spent a lot of time to complete a large number of sample collection and model training.

Meyer Tea Sorting Robot

"There is no shortcut to success, the results come out of the struggle!" With this determination and unremitting efforts, Meyer launched the first domestic tea sorting robot, filling the technical gap in China. Not only is it far ahead in performance, but it has also won the reputation of customers with its efficient service.

Based on the inspiration inspired by the robot sorting technology, Meyer launched the tea intelligent de-impurity sorter which is more suitable for the mass market, and successfully solved the problem of light impurities sorting under the demand of large output, and empowered the development of the industry with technological innovation.

Meyer new generation tea intelligent sorter

Return customer trust with technological innovation

Now, Meyer has been ploughing into the tea industry for 16 years. Looking back on this journey, many customers have a common feeling: we choose Meyer because of its well-known brand and better quality! Meyer always attaches great importance to our needs, timely response, continuous innovation, and responsible spirit.

Before 2008, tea sorting mainly relied on manual work, and only a very few tea enterprises could afford expensive imported equipment, and the results were not satisfactory. At that time, Meyer had already achieved a lot of results in the field of rice and grain sorting, so some people took the initiative to find the chairman of the company, Tian Ming, and hoped that Meyer could also develop its own tea color sorter.

There are many types of tea, and each piece of tea has a different shape, but also fragile materials, to achieve automated sorting is very difficult. But as long as it is done, it is a good thing for the country and the people! Mr Tian believes that since the country has a need, tea enterprises have demands, tea farmers and people are also beneficial, someone should do it! Meyer has the technology and ability to take up this important task!

With the advantage of combining industry, academia and research, Meyer soon succeeded in developing the first digital intelligent color sorter for tea in China. Soon, the Chinese Society of Agriculture evaluated the results, that the equipment has reached the international leading level. This effectively promotes the modernization level of tea processing in China and helps tea export.

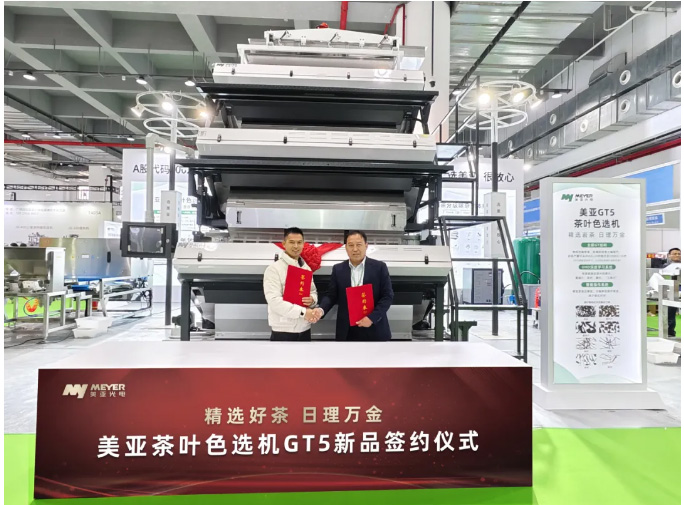

Customer purchased Meyer five-stage tea color sorter

Since then, Meyer has been ploughing into the tea industry, actively responding to customer needs, and always reminding itself that it should consistently uphold the spirit of contract to customers, so that quality and service throughout the implementation of each contract at the beginning and end. This spirit has enabled Meyer to win the market, win the trust of customers, and obtain a steady stream of development momentum.

Appreciate your support, let's move forward together!